A North Wales specialist steelwork fabrication company is reaping the rewards of a major programme of investment.

S4S (Steel 4 Structures) has opened a dedicated 11,000 sq. ft. paint facility at its base in Buckley and has won a series of major contracts.

They include the company’s biggest ever project – a flagship multi-storey car park at Alderley Park, Cheshire. The seven-storey galvanised structure provides 2,227 car parking spaces and included 1,200 tonnes of fabricated steel.

S4S, a specialist in the renewable energy sector, is also delivering a specialist pipe fabrication package at Hooton Bio Power in Ellesmere Port.

Hooton Bio Power is an energy-from-waste (EfW) plant that will utilise advanced conversion technologies to process 240,000 tonnes per annum and generate 25.2MW of electricity which will be exported to the grid after the facility’s own power needs are met.

These and other successes have enabled S4S to double its turnover despite the challenges of the Covid-19 pandemic.

The company is now planning the next phase of its growth plans including the recruitment of up to six new employees to bolster the current 30-strong workforce.

Buckley-based S4S was established by Managing Director Tom Phillips in 2010 and operates out of a 37,500 sq. ft. facility on the town’s Spencer Industrial Estate.

Its services include all aspects of structural steelwork and metalwork. S4S offers its clients a turnkey service from design, fabrication, finishing and site installation.

S4S has also carried out projects for a many household names in the retail, food and beverage and hospitality sectors including Costa Coffee, Greggs, Coca Cola, Heineken, Beefeater Gin, Home Bargains and Lidl.

The company has also provided new showrooms for major motor dealerships including Porsche and Jaguar Land Rover.

Roger Phillips, S4S’s Commercial Manager, said: “We have continually invested in the business to ensure that the services we are able to offer our clients are best-in-class.”

The company’s first major investment was one of only five Lincoln Electric Python X CNC robotic structural fabrication machines in the UK. This new technology provided the business with an increased capacity creating more jobs for fabricators and welders.

Investment continued with the introduction of an automatic blast line and two further CNC lines. The Voortman V550 plate and angle line and V320 CNC plasma and drill line has again created a larger capacity and better product for the company’s clients and, more importantly, giving the edge over its competitors.

Business Development Manager, Shaun Bebbington, said: “The ongoing investment has enabled us to grow our relationships with existing customers while, at the same time, attracting new business.

“Our sustained growth also owes a lot to the highly skilled and committed team we have developed. We are now looking to recruit a further six employees including platers, welders, and estimators. Our philosophy has always been about attracting people with the right attitude with the appetite to learn new skills.”

Pictured - Tom Phillips MD of S4S.

Blues Match Preview: Hereford v Chester FC

Blues Match Preview: Hereford v Chester FC

Ten arrested for drugs offences following warrants in Chester

Ten arrested for drugs offences following warrants in Chester

Ten arrested for drugs offences following warrants in Chester

Ten arrested for drugs offences following warrants in Chester

Suspended prison sentence and indefinite ban for Cheshire man who abused his dog

Suspended prison sentence and indefinite ban for Cheshire man who abused his dog

Recovered Stolen Items

Recovered Stolen Items

Man charged in relation to courier fraud

Man charged in relation to courier fraud

Police to target criminal use of Cheshire’s roads

Police to target criminal use of Cheshire’s roads

Council awarded Gold Armed Forces Award

Council awarded Gold Armed Forces Award

Appeal for footage and witnesses following collision in Delamere

Appeal for footage and witnesses following collision in Delamere

Appeal for information following serious collision in Chester

Appeal for information following serious collision in Chester

Your chance to get involved in police scrutiny meetings

Your chance to get involved in police scrutiny meetings

New Events at Jodrell Bank

New Events at Jodrell Bank

Inspiring Futures at The Queen’s School

Inspiring Futures at The Queen’s School

Bowmere Hospital celebrates 20 years of mental health care

Bowmere Hospital celebrates 20 years of mental health care

Man charged with burglary and drug offences following Chester police stop check

Man charged with burglary and drug offences following Chester police stop check

Vicars Cross Road closed following collision in Chester

Vicars Cross Road closed following collision in Chester

Man jailed for controlling and coercive behaviour and assault

Man jailed for controlling and coercive behaviour and assault

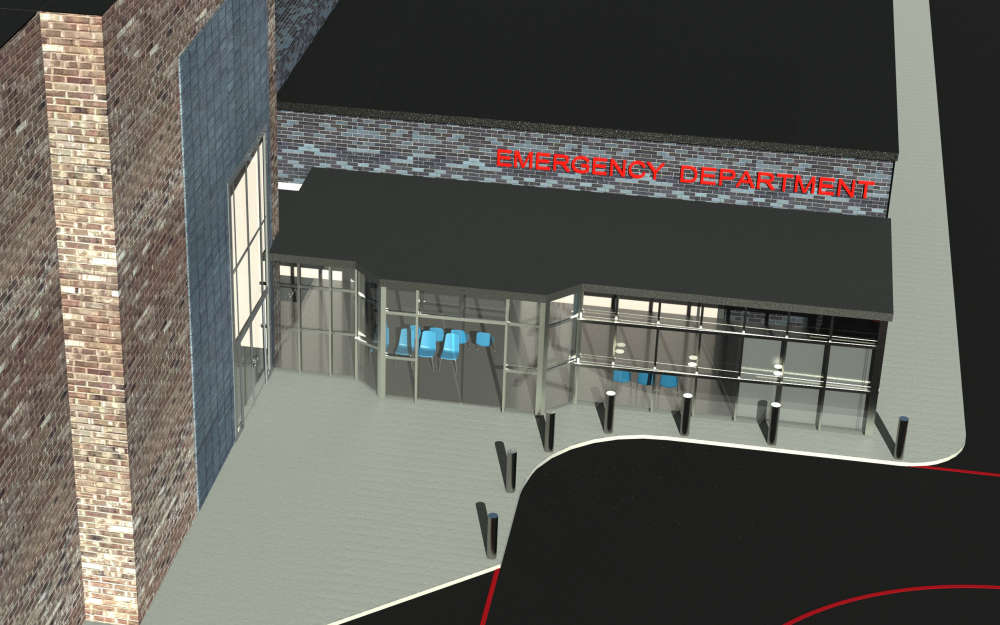

Plan unveiled to transform and improve emergency care at Countess of Chester Hospital

Plan unveiled to transform and improve emergency care at Countess of Chester Hospital

Chester & Wirral Football League - Weekend Round Up

Chester & Wirral Football League - Weekend Round Up

Comments

Add a comment